Research And Development

JOTON JSC is very interested in investment of testing and measure equipment to meet the control of product quality and R&D.

Joton’s laboratory, with fully modern testing and measure equipment imported from famous suppliers in the world, can carry out the exams and tests of paint and coating quality. Besides, the skill chemical engineers who are frequently trained on the quality management system and effective control methods to product quality and modern methods of testing under advance standards of product quality in the world, can carry out the exams and tests of not only paint and coating but also some another materials such as leather, rubber, plastic, polymer, composite etc.

BUREAU FOR ACCREDITATION/DIRECTORATE FOR STANDARD AND QUALITY, member of ILAC/APLAC MRA has been assessed and found Joton’s laboratory to conform to the requirements of ISO / IEC 17025 :2005 in chemical field, accreditation No VILAS 359.

Besides, VIETNAM REGISTER has been recognized Joton’s laboratory to conform to the Standard, Rule of Vietnam Register – VR, and equivalent, certificate of Laboratory No VR LAB. 37.

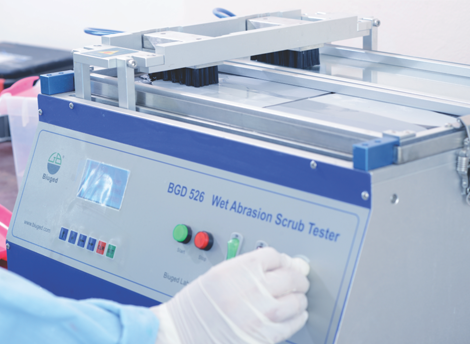

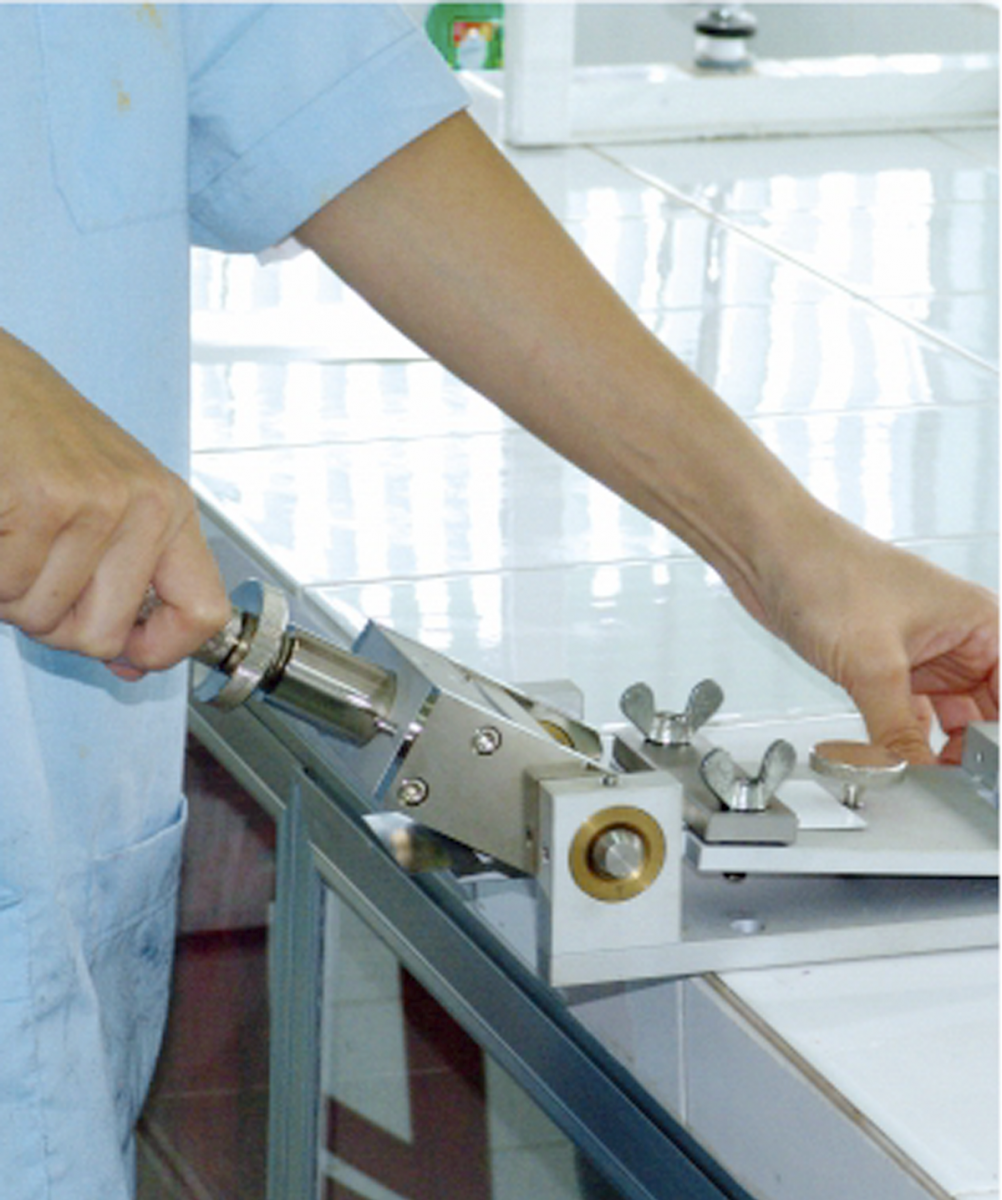

Laboratory Equipment System

- Washing and Scrubbing Resistance Tester (Erichsen / Germany)

- Abraser (Taber / USA)

- Viscometer–KU Krebs Unit and Pa,s Poise (Beookfield Engineering Labotatories / USA)

- Adhesion tester (BYK Gardner Gmb / Germany)

- Color guider measurement tester (BYK Gardner GmbH / Germany)

- Coating Amount (BYK Gardner GmbH/ Germany)

- Sagging and levelling tester (BYK Gardner GmbH / Germany)

- Cylindrical mandrel bend test Apparatus (BYK Gardner GmbH / Germany)

Q-FOG TESTER

- Improve correlation with outdoor result.

- Perform sophisticated cyclic corrosive test.

- Perform Prohesion® or traditional salt spray exposures.

- Conform to ISO, ASTM, BS, and DIN, automotive and industrial specification.

Accelerated Weathering Tester

QUV testing takes place in an accelerated weathering chamber, designed to create a highly flexible mix of UV light, temperature and moisture conditions. The tests are intended to reproduce the damage caused by sunlight, rain and condensed surface moisture or dew. The chamber subjects the test materials to alternating cycles of light and moisture at controlled elevated temperatures.

The moisture includes both condensing humidity, to simulate dew, and water sprays. The light in the chamber is created by specially-designed fluorescent UV bulbs to simulate the effects of sunlight. Although UV radiation actually only comprises about 5% of normal sunlight, the short-wavelength UV light does most of the photochemical damage.

Although no precise correlation can be made between accelerated test lengths and real-world exposure, the QUV weather meter reliably reproduces the damage that occurs over months or years outdoors. Samples can include all kinds of paint and coating, from latex to polyurethane and epoxies.

Types of damage include color change, gloss loss, chalking, cracking, hazing, embrittlement, and strength loss. QUV test data can help in selection of new materials, the improvement of existing materials or the evaluation of changes in formulation.

DANH SÁCH THỬ NGHIỆM ĐƯỢC CÔNG NHẬN