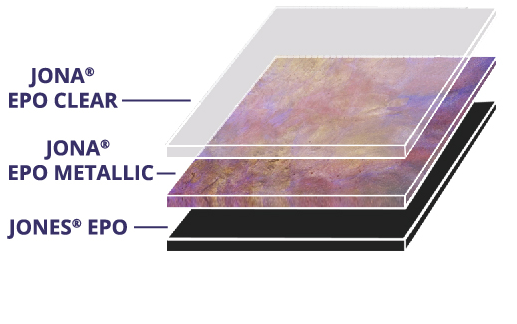

JONES® EPO

Surface material:

Bare steel: To get the best finish, the cleaning with abrasive blast should be conformed to SA 21/2, and the removing oil and grease with solvent should be conformed to SSPC-SP1. Shopprimed steel: Clean, dry and undamaged approved shopprimer. For the concrete surfaces, the wet cloths should be used for cleaning dirt and other same contaminants. The dilute detergent or solvent should be used for removing oil and grease. For exterior surfaces, jet-water can be used. Filling and leveling the holes and cracks on the surface with suitable materials. The rough surface will increase adhesion. The surface humidity is not more than 12%.

Typical applications:

Application for factories, machines and industrial components

Introduction:

JONES® EPO is a two-component epoxy primer, Polyamide or Amine curing agent. Compatible with most other high quality chlorinated rubber, Polyurethane and Epoxy paints.Used to increase adhesion, alkali prevention effect for coatings on concrete and anti-rust substrates to protect metal parts for industrial plants, chemical, fuel, sea water, and biological water tanks active ...

R: 255 G: 255 B: 255

Outstanding feature

Description

Used to increase adhesion, alkali prevention effect for coatings on concrete and anti-rust substrates to protect metal parts for industrial plants, chemical, fuel, sea water, and biological water tanks active ...

JONES® EPO has been certified as conforming to the JAPANESE INDUSTRIAL STANDARD JIS K 5551:2008

Features

Excellent/ high/ medium/ low

1 set : 16 kg (part A) + 4 kg (part B)

and 1 set : 3.2 kg (part A) + 0.8 kg (part B)

Store in cool dry place. Keep away from heat and ignition sources.

|

- Non-volatile content: min.55% - Density: 1.55 ± 0.05 g/ml - Diluent/ Cleaning: JOTHINNER®-300 - Mixing ratio by volume A/B:4/1 |

|

- Wet paint thickness: 90 µm - Dry paint thickness: 50 µm |

|

- Drying time (23 ºC): Surface dry after 4h, Hard dry after 16h - Cover next layer after (23 ºC): Minimum 16h - Life time (23 ºC): 7h |

On the standard surface.

|

1 PRIMER COATING Theoretical coverage: 5-7m2/kg/layer 50 µm. |

** Real coverage can change depends on color and surface condition.

** Apply on the floor covered by primer layer.

how to apply

Color selection method

Choose color from Joton website www.joton.com.vn / Choose color from product color chart

More

LOW VOCJOTON products do not include carcinogens, substance cause mutant and toxic substance. All substance cause pollution have content under 0.01% gravity. |

Note

| Stirr well before use | |

| Minimum surface temperature to apply is 10ºC and over dew point of the air 5ºC. Environment humidity to apply <- 85% | |

|

Drying time depends on temperature, humidity, ventilation degree of applying environment. High temperature and ventilation make paint dry more quickly. |

Health and safety

- Keep away from children- Ensure good ventilation condition during apply and dry time.

- Avoid to inhale paint powder.

- Should use protective glass when apply. When paint gets into eyes, wash with water and visit medical facilities immediately.

- Use suitable solvent to clean paint on body, then use water and soap to clean completely.

- Be careful during transport. Sprinkle soil or sand on to collect if paint poured out

- Pay attention to prevent explosion. Do not pour out paint to sewer and fountain.

.svg)

.png)